- Compact form-factor for simple installation

- Real-time, stable, repeatable and reproducible measurements in Newtonian & non-Newtonian fluids

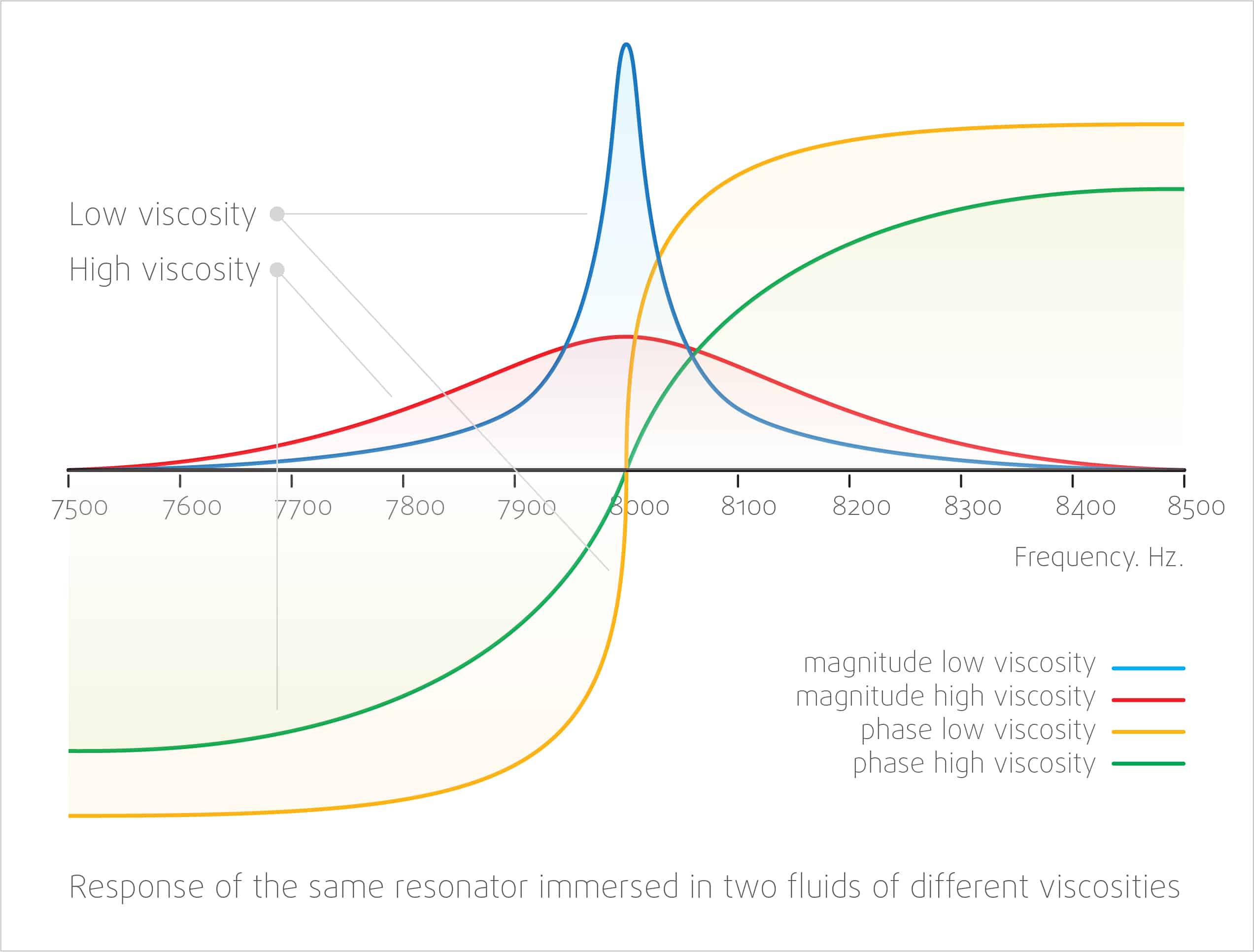

- Track viscosity change over wide range with one sensor

- All metal (316L Stainless Steel) construction

- Completely insensitive to mounting conditions

- Built in fluid temperature measurement

- Operational to 7500 psi (500 bar) and 575°F (300°C)

- Threaded, flanged and sanitary process fittings

- Easy to clean, no maintenance or re-configurations needed for scaling across the factory